Steel structure design is an important part of modern construction engineering. So what are the main contents of steel structure design? What information do designers need to provide when preparing to build a steel structure building? Are the design standards of different steel structure buildings the same? Today we will analyze these aspects in detail.

Table of Contents

1. What aspects does steel structure design include?

- Structural scheme design: Because different structural schemes are usually selected for different building functions, such as frame structure, truss structure or grid structure. Choosing a suitable structural form is the first consideration for designers. This is the first factor to ensure building safety and meet building functions. At the same time, economic efficiency and construction convenience should be considered to optimize the amount of steel used.

- Load analysis and calculation: Load is the basis of steel structure design. The design needs to fully consider permanent loads (such as self-weight), variable loads (such as wind loads, snow loads) and accidental loads (such as earthquake loads). Ensure the safety and economy of the design, especially the reliability under extreme conditions.

- Material selection: The steel types in each country are different. For example, American standard steel generally uses A36 steel plate, ASTM standard; European standard H-shaped steel has a variety of steel grades, the common ones are S235JR, S275JR, S355JR, S355J0, S355J2, etc.; the inter

- national standard is generally Q235 and Q345, etc. Moreover, the design standards and building specifications of each country are also different, and the design drawings need to be stamped by the designer of the country to take effect.

Designers need to choose the appropriate type and specification of steel according to the function and environmental conditions of the building. The strength, toughness and durability of steel should be considered in the design to ensure the quality and safety of the building.

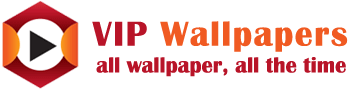

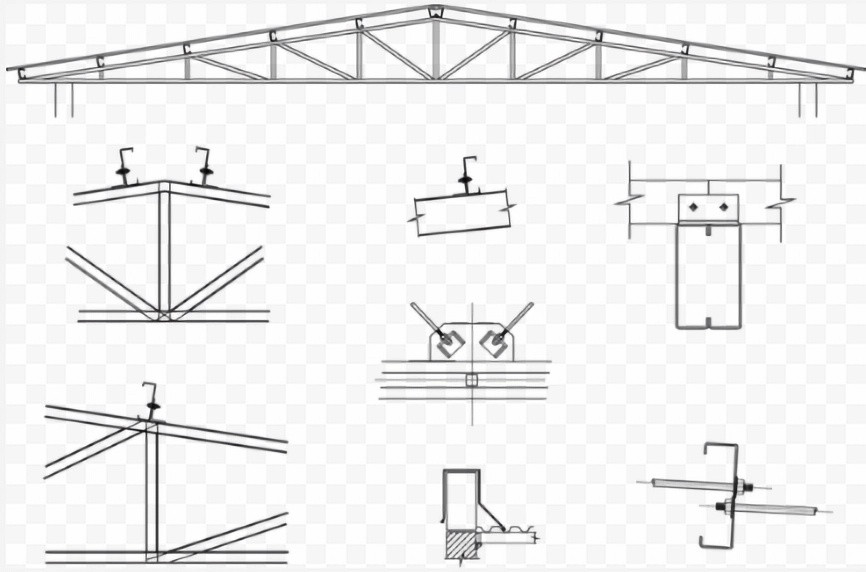

- Component design and connection method: beams, columns, trusses and other components in steel structures must meet the requirements of strength, stiffness and stability.

The connection method can be welding, bolting or riveting. The seismic performance and construction convenience should be weighed during the design. The node design should be clear.

- Earthquake and wind resistance design: For earthquake resistance design, the stiffness distribution of the structure should be optimized to avoid unnecessary stress concentration.

Wind resistance design should ensure structural stability based on the building height, shape and local wind environment.

- Anti-corrosion and fire protection design: Steel structures are easily corroded by environmental factors, and the design needs to adopt anti-corrosion coatings, hot-dip galvanizing or weathering steel and other measures. For fire protection, fire-retardant coatings or refractory materials should be used to improve the durability of the structure under high temperature conditions.

2. Information that needs to be provided to designers for steel structure design

In order to ensure the accuracy and construction feasibility of steel structure design, the following information needs to be provided to designers:

Project background

Building purpose: clarify whether the building is used for industrial plants, bridges, high-rise residential buildings or other purposes.

Design requirements: such as service life, fire protection level, earthquake resistance level, etc.

Site conditions

Geological report: including detailed information such as soil type, bearing capacity, groundwater level, etc.

Environmental conditions: wind and snow loads, earthquake parameters and other external environmental influences.

Building parameters

Building floor plan, functional zoning, and floor height requirements.

Requirements for special structural forms or building heights.

Load information

Specific values of various loads, including equipment loads, personnel loads, etc.

Dynamic loads or impact loads under special circumstances.

Materials and specifications

Specify the types, specifications, and relevant standards of steel materials to be used.

Specific requirements and construction specifications for anti-corrosion and fireproof materials.

Construction conditions

Construction environment restrictions, such as site size, equipment use conditions, etc.

Construction period requirements and transportation and hoisting conditions.

Special design requirements

Appearance and functional requirements, such as modular or prefabricated building requirements.

Whether future expansion or renovation needs to be considered.

3. Design standards for different steel structure buildings

The design standards for steel structure buildings vary depending on the purpose and function of the building. The following are the design features of the main building types:

- Industrial plant:

The focus is on large-span design to ensure open space and facilitate the operation of industrial equipment. Generally, a portal frame structure is used.

Meet the requirements of dynamic loads, such as crane loads or production equipment loads.

The roof design needs to be lightweight to reduce deadweight and cost.

- High-rise and super-high-rise buildings

High-rise buildings need to focus on earthquake resistance and wind resistance, and adopt steel frame-core tube structure.

Use high-strength steel to reduce deadweight and optimize foundation design.

The design needs to take into account both aesthetic appearance and structural economy.

- Bridge structure

The bridge design needs to meet the requirements of vehicle load, wind load and seismic load.

Long-span bridges often use cable or steel truss structures to ensure economy and stability.

Pay special attention to fatigue design to ensure the long-term safety of bridges.

- Stadiums and exhibition centers

Use large-span spatial structures, such as grids or tensile membrane structures, to meet large space requirements.

The structural design needs to take into account complex modeling and functional requirements. Consider the audience load and good ventilation and lighting requirements.

- Prefabricated steel structure buildings

The design needs to meet the requirements of modular production and rapid installation. Focus on the reusability of node design to improve the recycling rate of buildings. Modular design is highly standardized and suitable for a variety of building uses.

Conclusion

The scientificity and accuracy of steel structure design directly affect the safety, durability and economic benefits of buildings. From the core points of the design to the information provided and the design standards of different buildings, steel structure design requires a comprehensive balance of building functions, environmental conditions and construction processes. In the future, with the advancement of technology, steel structure design will be more intelligent and green, providing more efficient and environmentally friendly solutions for the construction industry.